MickeyMoto wrote: ↑10 Jul 2024 06:46

Ouch.

Careful when you remove the barrel in case any swarf is dragged down the bore. Might be worth oiling around the piston.

You probably need a helicoil or similar. This will require a drill to be at the exact angle. I would not attempt it. Look in the classic bike mags for people who can do it. Might be worth checking the other head, too.

The washer must have been in the cylinder when you rebuilt the engine, I doubt it would have come through the inlet port, unless it dropped in from the inlet manifold before you started the engine. The only washer close enough that thickness would be in the pushrod tunnel but that would go on after the head was attached. I think you would have noticed an errant washer on the piston crown.

Thanks for the tip on checking for and removing any swarf. I'm going to vacuum first, then I'll add some oil around the bore, and do whatever I can to minimise any swarf remaining in the piston/head/barrel/rings/engine.

I watched several hours of videos online and also compared various approaches to repairing the spark plug thread to decide which method looked most promising and then somewhat connected who should do the work (me, my local motorbike shop where I know several of the mechanics, or a specialist).

- The best quality repair is probably one using the Würth timecert inserts. Their tooling for the inserts looks to work phenomenally well in terms of aligning the repair, cutting seats, etc. The main downside is cost, probably £400 for the kit and roughly £20 per insert in small volumes (dropping to £15 for a pack of 10 of the longest M14x1.25mm insert they sell, 16.8mm).

- There are numerous 'knock-offs' that have similar approach to cutting the thread and seats, etc. for 1/5 to 1/10th of the Würth tooling. For example from Sealey, Neilsen, and from US Pro. Reviews of these and other very similar products generally complain the inserts are poor quality in some circumstances (but generally OK in aluminium head material).

- There are even more basic tools, some with a drill and a single tap, some simply with a tap, and then various inserts. These are as little as £10 - £15 ish. None looked worth using.

- Genuine HeliCoil kits are available for £61, and similar offerings range from over £110 to under £20. I just discovered I'd bought one of these and squirrelled it away

- Specialist aluminium welding and recreating the thread.

Last night I ordered the kit from US PRO, their "Tools Thread Repair Kit For Deep Seated Spark Plugs M14 x 1.25 NEW 5916", no less. It cost about £45 including p+p. When this arrives I'll have two choices I can try using (the inexpensive helicoil look alike) and the US Pro kit that uses inserts.

I'm reasonably confident the US PRO tooling would align the new thread in the cylinder head adequately. Here's the video that convinced me

https://www.youtube.com/watch?v=CYdSqWDWSFU which admittedly uses the genuine Würth tools and inserts. Optionally I could set up a test on a sacrificial head e.g. using a more knackered cylinder head (I have one with widespread erosion similar to

viewtopic.php?f=4&t=7787 but more widespread slightly shallower cavities) or or piece of aluminium of a similar thickness (I don't have any suitable blocks though).

I suspect the helicoil look alike would also be adequate and less prone to 'the insert being too large a diameter to fit' as reported by people who'd bought the Neilsen kit for example

https://www.amazon.co.uk/Spark-Thread-R ... 00J06J3M6/

In terms of the source of the washer. I agree the two most likely sources are when I was fitting washers to either the M7 rocker block or the M6 cap head bolt for the pushrod holes. I did faff around with various lengths of the M6 cap head bolt (30, 35, 40 mm thread lengths) as the old ones weren't to hand; and I might well have tried 2 washers on the 40mm thread length. Any of this work though would have been when the head was on the barrel, either before the head was bolted down or afterwards. I probably fitted the spark plugs after the rockers were fitted but can't remember the details. So there's the potential for the washer to have entered via the spark plug hole.

However if the washer entered when I assembled the engine why didn't it make an appearance earlier? I'd run the engine many times (at least 20 times) over the last few weeks, mainly in neutral outside the garage and only up to about 4k to 5k rpm with a temporary fuel tank and very brief 10 metre rides on the drive to see if the gears engaged, and to free the wet clutch. I fitted the airbox relatively late in the process; I'd split it to check the filter and to clean it. There are M6 flat washers used to hold the airbox to the frame but highly unlikely that they'd end up in the internal area of the air box in my view.

The clattering only happened after the test ride on the road and the damage looks consistent with infrequent contact with the head and valves. Also the bike was probably running on both cylinders (and the rear seemed the livelier of the two). The washer

could have rested in one of the cutouts for the valve pockets in the piston but that seems unlikely that it would only free itself / move after the test ride when I restarted the bike on the drive.

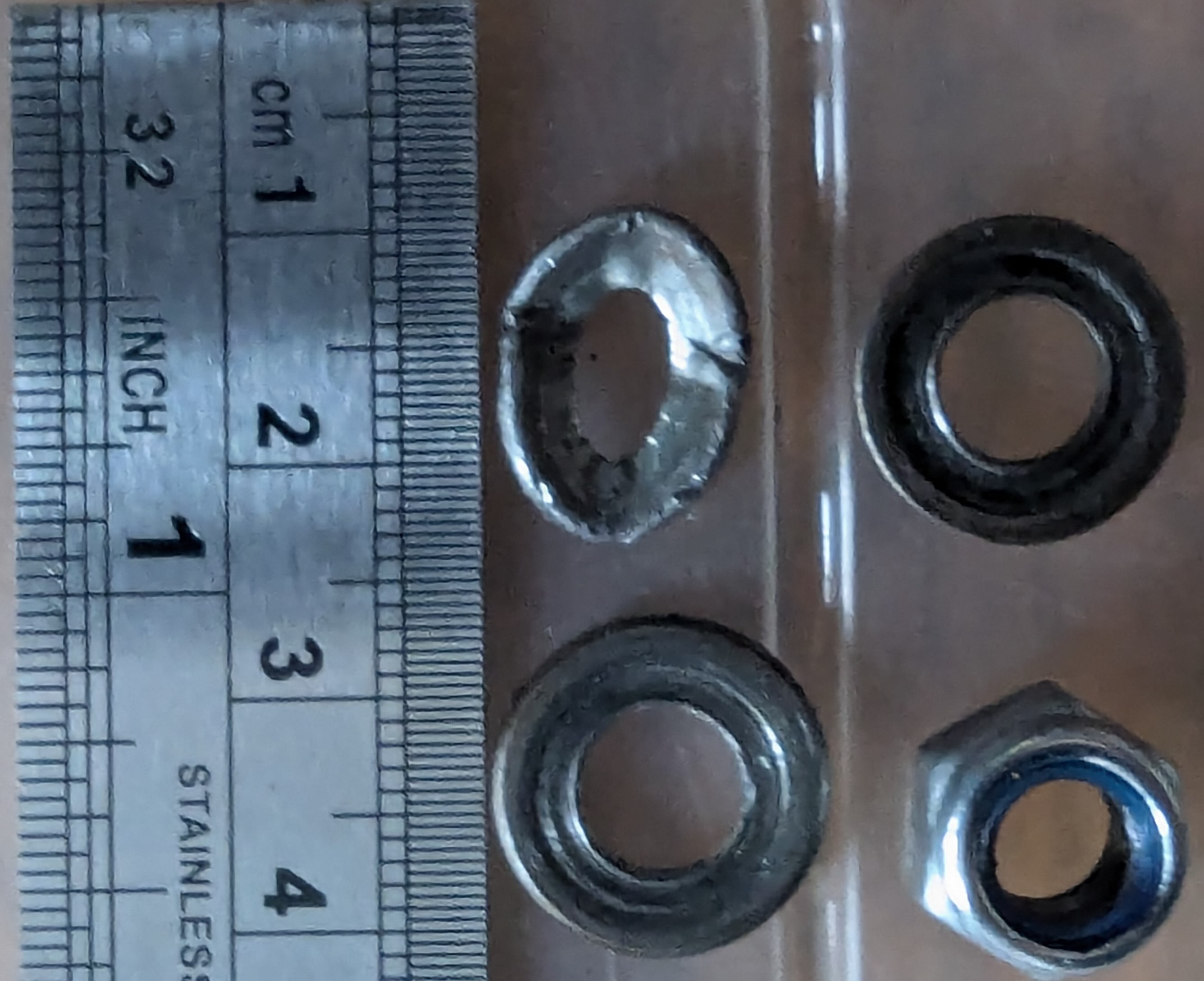

I've taken some measurements of the damaged washer and the M7 rocker washers. I used a low cost but reasonably good micrometer, the rule is to help show scale on the photo. All measurements are approximate owing to the limitations of the measuring tools I used and my abilities in using them.

- M7 rocker washers are: 14.2mm OD, 7.0mm ID, 1.4mm thick. Measured difference in radius 3.5 to 3.7mm.

- Damaged washer's dimensions have mins and maxes because of the oval shape of it: OD max 14.3mm min 10.5mm, ID 4.1mm to 7.1mm, thickness varies between 1.3mm and 1.7mm, most of it is 1.4mm. Measured radius 3.3 to 3.4mm.

Visually the damaged washer has a different profile; as Mark observed the M7 rocker washers seem to have a bevelled edge, this washer doesn't have the same profile. I'm leaning to it being an M6 washer rather than one of the M7 rocker washers but not 100% confident in this assessment. I've found standard dimensions for M6 and M7 washers online e.g.

M6 A2 OD = 12mm and

M7 A2 OD = 14mm on the accu.co.uk website.

- damaged washer compared to rocker m7 washers.jpg (503.34 KiB) Viewed 9443 times

PS: Yes I hope I'd have noticed a washer sitting on top of the piston!

IIRC I'd fitted the cylinder heads, etc. while the engine was in an engine stand; and that I'd done the tappet adjustments with the engine in the frame. However I may have misremembered especially as I've got a lot of other stuff going on.